What is AI & ML in Industry 4.0?

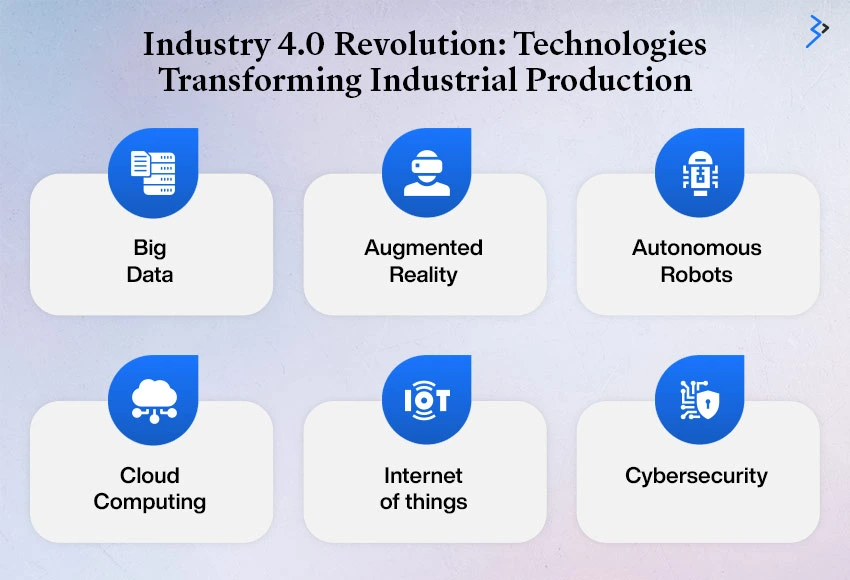

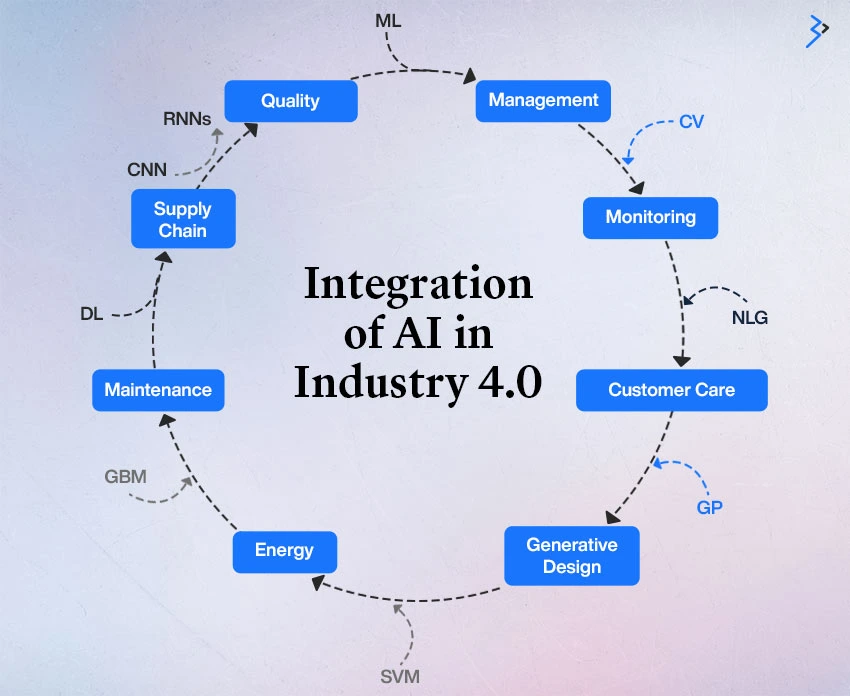

“Industry 4.0” refers to the fourth industrial revolution, which combines digital technologies with physical processes in manufacturing and industry. Artificial Intelligence (AI) and Machine Learning (ML) are at the heart of this transformation, technologies that move beyond traditional automation into intelligence. AI refers to machines simulating human intelligence to perform tasks. At the same time, ML is a subset of AI where machines learn from data and improve their performance over time without explicit programming.

In Industry 4.0, AI and ML are crucial in enhancing efficiency, predicting outcomes, and optimizing operations across sectors. Integrating these technologies transforms industries from merely automating repetitive tasks to creating intelligent systems capable of adapting, learning, and improving.

Transition from Traditional Automation to Intelligent Systems

Traditional automation typically involves pre-programmed mechanical tasks, such as assembly lines or conveyor belts operating on repetitive sequences. However, the shift towards intelligent systems means these machines can now collect data, analyze it, and make decisions autonomously. This leap from rigid, rule-based processes to dynamic, self-learning systems marks the critical transition from automation to intelligence in Industry 4.0. In modern industries, AI & ML are not just tools for automation but critical drivers of decision-making, operational efficiency, and predictive maintenance.

[ Read More: Top 18 AI Product Description Generator Tools To Use in 2025 ]

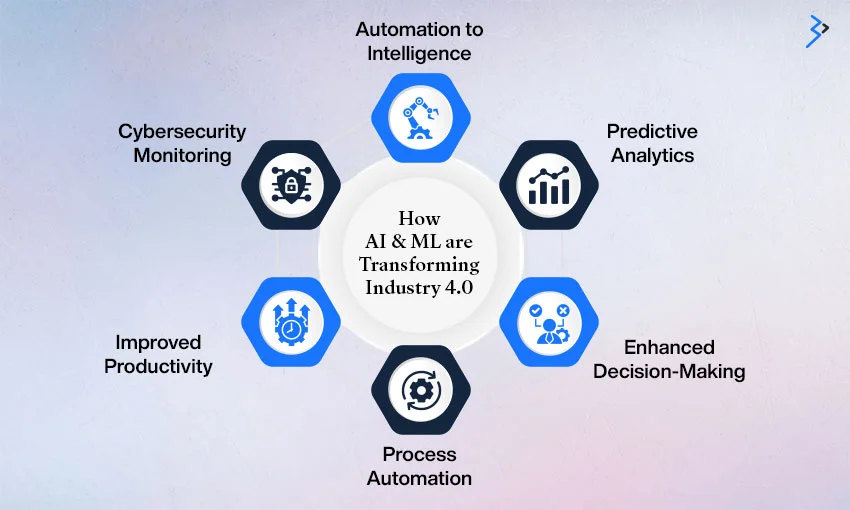

How AI & ML are Transforming Industry 4.0

- Automation to Intelligence

The evolution from basic automation to intelligent automation represents one of the most profound changes brought by AI & ML. Basic automation relies on machines executing predefined tasks without any room for adaptation. For example, traditional manufacturing robots would only perform the same task repeatedly, regardless of environmental changes.

In contrast, intelligent automation involves systems that can learn and adapt to new data and circumstances. These self-learning systems can adjust production processes, predict machine failures, and even recommend improvements based on real-time data. AI and ML have become game-changers in the manufacturing, logistics, and healthcare industries, optimizing everything from supply chains to product quality.

For instance, in manufacturing, AI algorithms analyze machine sensor data to detect signs of wear and predict failures before they happen, preventing costly downtime. In logistics, AI-driven optimization has reduced delivery times and improved supply chain visibility, resulting in higher efficiency and lower costs.

- Predictive Analytics and Maintenance

Predictive maintenance is one of the most valuable applications of AI & ML in Industry 4.0. Industrial processes often rely on heavy machinery that requires regular maintenance. However, traditional maintenance schedules based on historical data or routine checkups usually result in unnecessary downtime or unexpected failures.

AI and ML enable predictive analytics, allowing companies to foresee when a machine is likely to fail based on real-time data, such as vibration patterns, temperature, or pressure levels. This shift from reactive to proactive maintenance leads to significant cost savings, extended equipment life, and improved productivity.

For example, companies like General Electric use AI to monitor the health of their industrial turbines in real time. With predictive models, they can identify potential breakdowns and perform maintenance only when necessary, thus avoiding unnecessary downtime and extending the lifespan of their machinery.

- Enhanced Decision-Making

In Industry 4.0, decision-making has become more data-driven and less reliant on human intuition. AI & ML algorithms process vast amounts of data at high speeds, offering insights that would otherwise take humans much longer to uncover.

AI-driven systems have proven far more efficient than traditional production scheduling, inventory management, and demand forecasting methods. For instance, AI can analyze sales trends, predict future demand, and adjust inventory levels accordingly, preventing overstocking and stockouts.

Take the case of retail giant Amazon. AI algorithms power their inventory management system, predicting customers’ buying patterns and ensuring products are stocked accordingly. This level of precision would only be possible with human-driven processes.

[ Read More: AI-Driven Personalized Product Recommendation: Use Cases and Benefits ]

What Are the Challenges of AI & ML in Industry 4.0?

- Operational Complexity

While AI & ML promise substantial benefits, their complexity can act as a barrier to widespread adoption. Integrating these technologies into existing industrial operations often requires specialized knowledge and skills. Companies may need help finding the expertise to maintain these systems and ensure they function correctly.

Moreover, the infrastructure needed to support AI and ML, such as data processing capabilities and advanced computing power, can be costly. Industries must be prepared to invest in the software and the broader ecosystem that allows AI to thrive.

- Customization and Adaptability

Another challenge industries face when adopting AI & ML is the difficulty of customization. Every industry, and indeed every company, has unique operational requirements. A one-size-fits-all AI solution may not always work, so customization is crucial.

However, creating tailored AI and ML solutions takes time and requires a deep understanding of the industry and a company’s specific challenges. Furthermore, as market conditions evolve, AI systems must also be adaptable to ensure long-term effectiveness.

Data Quality and Management

AI and ML rely heavily on data to function. However, not all industries can manage the vast data to train these systems. Poor data quality, data silos, and inconsistent formats can all hinder the effectiveness of AI & ML.

To maximize the potential of AI & ML, companies need to ensure that their data is well-managed, easily accessible, and of high quality. This requires significant effort in data collection, storage, and processing, which can be a challenge for industries that are not traditionally data-driven.

Scalability and Performance

Finally, scalability is a primary concern when implementing AI & ML in large industrial operations. As data volumes grow and operational complexity increases, maintaining consistent performance becomes more difficult. AI systems must be capable of scaling up without sacrificing accuracy or speed, which can be a daunting technical challenge.

[ Read More: Azure AI – Building Intelligent Applications ]

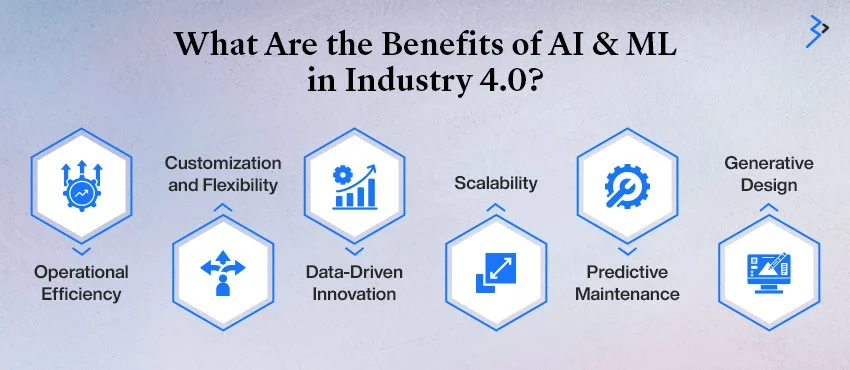

What Are the Benefits of AI & ML in Industry 4.0?

- Operational Efficiency

AI & ML technologies dramatically improve operational efficiency by automating complex tasks and optimizing resource allocation. Whether it’s reducing waste in manufacturing or minimizing downtime through predictive maintenance, AI helps industries operate more smoothly and at lower costs.

For example, AI-powered systems can streamline assembly lines, optimize energy usage, and even automate tasks like quality control, allowing human workers to focus on more strategic initiatives.

- Customization and Flexibility

Another key benefit of AI and ML is their ability to offer customization and flexibility. In today’s dynamic markets, businesses must be agile, adjusting their operations to meet changing consumer demands. AI and ML allow for creating highly customizable products and services, driving customer satisfaction and enabling industries to remain competitive.

For example, in the automotive industry, AI-driven systems enable manufacturers to customize vehicle features based on customer preferences, offering a higher level of personalization than traditional production methods.

- Data-Driven Innovation

AI & ML are at the forefront of data-driven innovation. These technologies allow industries to identify new opportunities, optimize processes, and develop innovative business models by analyzing large datasets.

In finance, for instance, AI detects real-time fraud by analyzing transaction data patterns. In healthcare, AI models help identify potential disease treatments by processing vast amounts of patient data, accelerating the development of new therapies.

- Scalability

One of AI and ML’s most significant advantages is their scalability. These systems can handle increasing data volumes and operational complexity without losing performance, making them ideal for industries looking to scale their operations or enter new markets.

For instance, cloud-based AI platforms allow companies to scale their AI capabilities across multiple geographies and operational divisions, ensuring consistent performance and adaptability to local market conditions.

[ Read More : Blockchain Integration in Industry 4.0: Trends, Challenges, and Opportunities ]

AI & ML vs. Traditional Industry Approaches

| Feature | Traditional Industry Approaches | AI & ML in Industry 4.0 |

| Automation | Rule-based, limited to predefined tasks | Intelligent systems that learn and adapt |

| Data Processing | Manual or semi-automated data analysis | Automated, real-time data analysis with AI |

| Decision-Making | Human-driven, based on historical data | AI-driven, predictive, and data-driven |

| Scalability | Limited by human intervention and legacy systems | Highly scalable with self-learning algorithms |

Transformative Impact of AI & ML: Case Studies in Integration

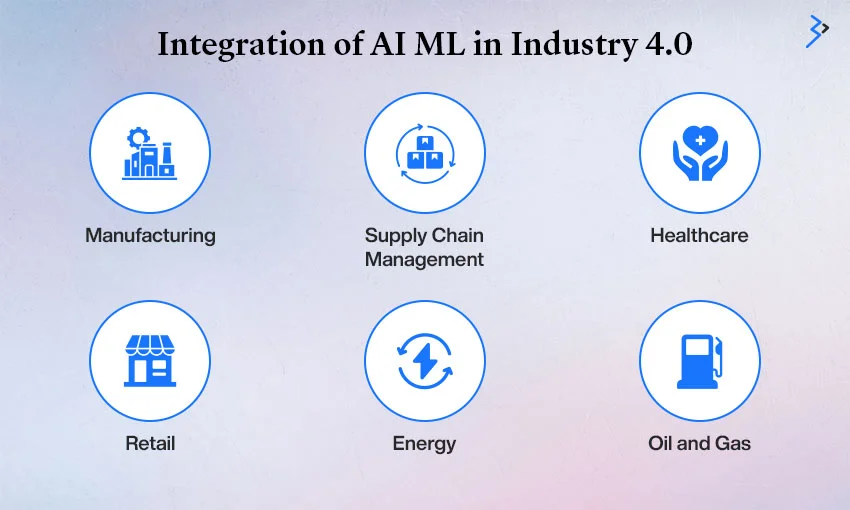

- Manufacturing Sector

- Use Case: A leading automotive manufacturer needed to reduce equipment downtime and inefficiencies in their production line.

- Transformation: AI-powered predictive maintenance allowed real-time monitoring of equipment health. Machine learning models predicted failures, reducing downtime by 30% and boosting production efficiency by 25%.

- Supply Chain Management

- Use Case: A global logistics company struggled to track shipments, ensure timely deliveries, and manage complex supply chain networks.

- Transformation: AI-driven analytics provided real-time shipment insights, optimizing routes and reducing delays by 20%. Machine learning improved demand forecasting, enhancing inventory management across the chain.

- Healthcare Sector

- Use Case: A hospital aimed to enhance patient outcomes through personalized treatment plans and predictive diagnostics.

- Transformation: AI algorithms analyzed patient data to predict health risks and suggest personalized treatments, improving patient outcomes by 15% and reducing readmission rates by 10%.

- Retail Sector

- Use Case: A retailer wanted to optimize inventory management and personalize customer experiences.

- Transformation: An efficient AI-driven demand forecasting system was implemented, reducing stockouts by a major 30% and increasing customer satisfaction. Our transformative application led to a about 20% boost in sales.

- Energy Sector

- Use Case: An energy provider sought to optimize distribution and reduce downtime in the grid.

- Transformation: AI-driven automation systems detected the grid performance, did comprehensive analysis while monitoring real-time, and predicted maintenance requirements. Advanced machine learning models were used to optimize energy distribution, thereby reducing operational costs by 15% and improving grid reliability.

FAQs

1. What technical expertise is required to implement AI & ML in Industry 4.0?

Implementing AI and ML in Industry 4.0 requires data science, machine learning, and programming skills. Knowledge of industrial processes, data engineering, and cloud computing is essential. Additionally, expertise in data preprocessing, algorithm development, and understanding of IoT and cybersecurity strengthens the deployment of AI-driven industrial solutions.

2. How do AI & ML integrate with existing industrial systems?

AI and ML integrate with existing systems through APIs, IoT devices, and data integration platforms, enabling seamless data flow and analytics. By connecting to sensors, PLCs, and industrial software, AI can analyze real-time data, enhance automation, and optimize processes, adapting to industrial infrastructure without disrupting operations.

3. What are the key challenges in adopting AI & ML in Industry 4.0?

Challenges include high implementation costs, data quality issues, and a limited AI-trained workforce. Integrating AI with legacy systems is complex, and ensuring cybersecurity adds further complexity. Additionally, regulatory compliance and adapting AI solutions to specific industry needs pose significant hurdles in effectively adopting AI and ML technologies.

4. How do I measure the success of AI & ML implementation in industrial processes?

KPIs like operational efficiency, downtime reduction, and production cost savings measure success. Metrics such as predictive accuracy, reduced maintenance, and improved decision-making speed are also considered. Consistently monitoring performance indicators and ROI helps evaluate the tangible impact of AI and ML on industrial processes.

5. What resources are available to learn about AI & ML in Industry 4.0?

Resources include online courses from Coursera and edX, industry-focused conferences, and professional certifications. Books, research papers, and industry reports provide insights into practical applications. Joining communities such as IEEE and AI-focused industrial forums helps people stay updated on industry advancements.

6. How can AI & ML improve sustainability in Industry 4.0?

AI and ML support sustainability by optimizing energy use, reducing waste, and improving resource efficiency. Through predictive maintenance, they minimize equipment wear, extending machinery lifespan. Additionally, AI models enable eco-friendly production processes, while real-time data analytics help industries monitor and reduce their environmental impact.

7. What are the ethical considerations when implementing AI & ML in Industry 4.0?

Vital ethical considerations include data privacy, algorithmic transparency, and addressing workforce displacement. Ensuring unbiased data use, preventing misuse of AI insights, and maintaining accountability are essential. Transparent, fair practices help build trust in AI and protect employee welfare and sensitive industrial data in Industry 4.0 applications.

Start with AI & ML in Industry 4.0

Are you keen to integrate AI & ML in Industry 4.0?

Our comprehensive services for your industry will enable you to take a leap of growth and propel your company toward scalability and prosperity. Contact us today!

Related Articles

-

The Future of Business Is Here: Artificial Intelligence and Odoo ERP

Businesses have unquestionably transformed in recent years thanks to artificial intelligence (AI), which has opened up previously unimaginable opportunities for expansion and reinvention. Odoo Enterprise Resource Planning (ERP) has also

-

From Manual to Intelligent: How AI and RPA Are Redefining Customer Support

Do you recall the days when customer service was on a never-ending series of phone menus, boilerplate mail answers, or days to wait to get a call back? Such days

-

How Generative AI Is Revolutionizing Contract Review: Faster Approvals, Lower Risk

Contracts can make or break deals, partnerships, and even business units. Yet for decades, reviewing them has been one of the job’s most tedious and frustrating parts. Legal teams and