In this blog, you will learn more about the picking guide. Suppose you have a warehouse or want to study the inventory module for picking, scanning, and packing for your business. In that case, it is incredibly beneficial for you to choose the type of picking that truly matters. If you have not yet established your warehouse inventory, please contact Brainvire Infotech.

We’ll try to show you how to choose several sales orders in a single pass, reduce wandering and over-routing; and, select and categorize items from diverse sales orders.

Shippers may customize picking techniques and adjustments using multiple warehouse management applications for Odoo enterprise and community available in the App Store and PlayStore.

Basic Info

Users with hands-on expertise in Warehouse or Inventory Management App or compliant with current settings may skip the basic information and go straight to the Odoo Inventory guide.

Configuration

Navigate to Inventory for the Configuration and click on the Warehouse Management to select the Operations Types.

Select the sort of operation you wish to do using your mobile device.

Tick the ‘Available on Mobile’ box.

[Also Read: Instructions on How to Integrate Odoo WorldPay Payment Gateway]

There’s also an option to add two more settings: ‘Create backorder’ for the confirm picking on the section called ‘Mobile App’ to generate a by default backorder;

Select ‘Product fields’ and add more custom fields to the mobile app.

How to Use?

Database section is required if your instance has multiple databases

Join and confirm your credentials

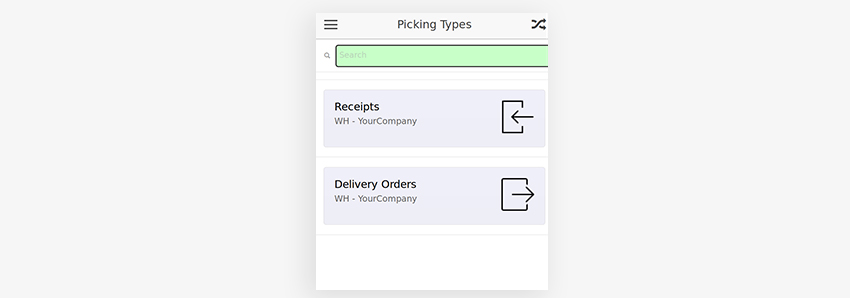

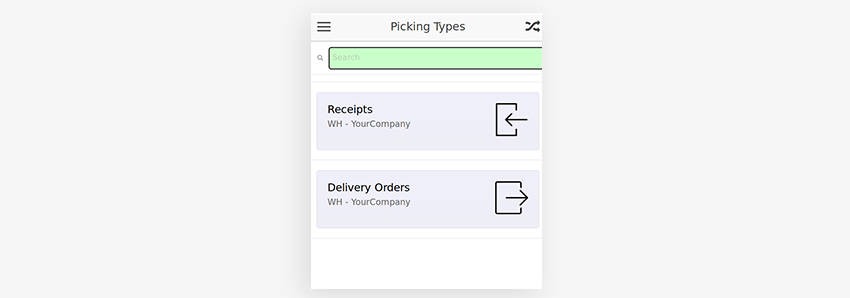

Choose the picking type you need

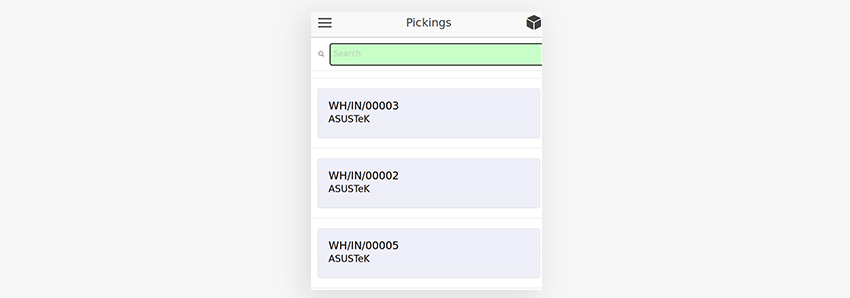

Choose the picking

There are two primary techniques for picking numerous orders for using a warehouse: cluster picking and batch picking. You’ll be able to find more information about these approaches when you talk to Odoo ERP development services. Both methods enhance the speed with which products may select using a barcode scanner.

- Picking in Bulk (Batch Picking)

You mix groups of purchase orders and may begin choosing right away. This approach is helpful to reduce the number of times a customer goes to similar stocked products at the exact location.

- Picking in Groups (Cluster Picking)

First, you must allocate each order to a specific container. Then, while selecting, all selected goods will be arranged by relevant costs. Therefore, specifically built these improvements for the inventory management App to boost the primary batch picking feature of Odoo.

(You have an option to scan the barcode)

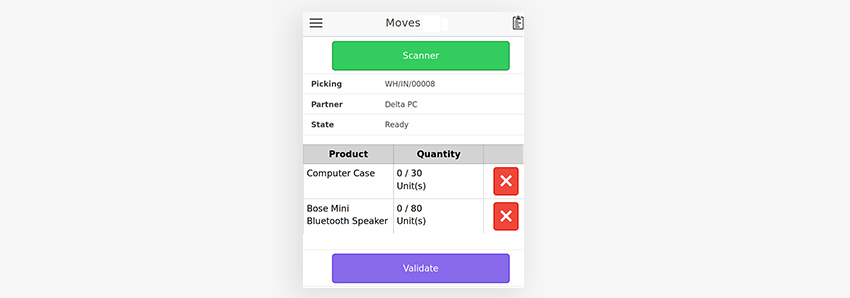

The details of the actions are displayed on the following screen.

Click the ‘Scanner’ option to access the scan screen.

You may also choose a moving line by clicking on it.

Scan the barcode on the product:

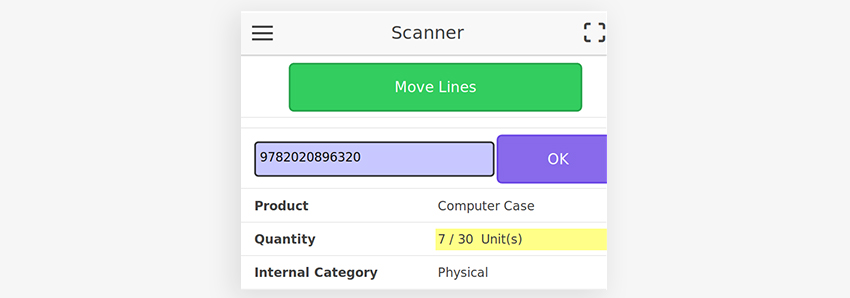

This will show the operation’s specifics. (anticipated and completed amount, UoM, and any additional fields you may have specified in the selecting type setup)

Each time you scan an item, the completed quantity increases by a single number.

The user can also provide a customized amount/quantity in the box if your system can easily calculate the number of items.

Return to the ‘move lines’ list by selecting the appropriate button after the process.

If you made an error, you might reset the quantity by clicking the button at the end of every line.

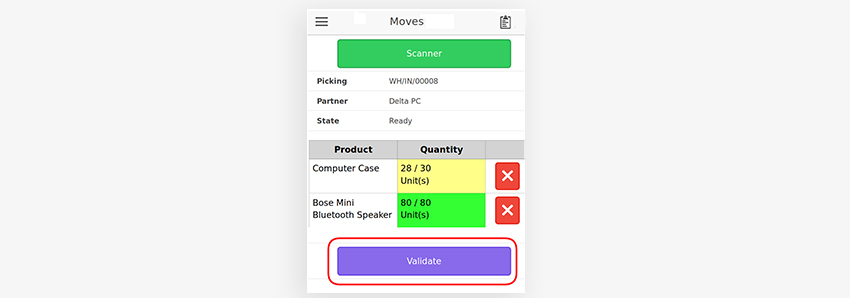

Once you’re done picking, select the ‘Validate’ key.

Based on the picking typesetting, it will either generate a shipment notification or it will not.

When validated, the display will move on to the next picking.

Colors vary according to the Quantity

Based on the difference between intended and finished quantity, each field quantity will get a distinct background color:

White indicates no quantity set; Yellow indicates that the expected amount has not been met; Green indicates that the done quantity equals the planned quantity; Red: the completed quantity exceeds the intended quantity.

Bugs and Warnings on the Login Screen

If the user is not a part of the ‘Warehouse / User’ group, they will be unable to access it.

Scanner Screen Errors and Warning

If the quantity specified is negative or not available, it will be marked as ‘incorrect quantity.’

If the operator attempts to scan an item that is not in the listing of the move lines, the message ‘Barcode not found in the picking’ appears.

[Also Read: Check Out an Intriguing Feature of Odoo 13]

‘Many operations found’ if there are several lines with similar items. In that scenario, the user must manually pick the line to be treated.

Optimization of Routing

Outgoing routing in the inventory management system module for Odoo also enables extra route calculations based upon plan and order.

You can read Odoo’s inventory application guide about locations naming

Following the setting up of location sequencing, the inventory management system routes the pickers with the help of a routing strategy.

Should note that it should enable the app’s ‘Show next product’ setting.

Conclusion

Using the optimization as mentioned above process for the warehouse helps you carry more items via your inventory faster than before, boost customer relationships, and encourage them to revisit for more purchases. For additional workable setups in the mobile application, we propose installing inventory mobile app base modules. For more details, reach out to Brainvire, one of the world’s top Odoo ERP development services providers and Odoo Gold Partner.

Read more: Odoo ERP Integrations: Payment Gateways, Social Media, SMS Gateways, Biometric Devices

Related Articles

-

Odoo 15 Vs 14 – Find the Differences!

The creators of Odoo, a well-known open-source ERP solution and business software, have completely integrated them into a powerful and flexible management software that can handle a range of business

-

Inbuilt Spreadsheet with Odoo-14: The Secret to Improve Business Functionality

Odoo ERP is a blessing for modern-age companies as it improves business functionalities and activities. Digital businesses prefer automated internal and external processes that run on smart technologies. With an

-

Learn more about the Kanban, one of the smartest Odoo views

Odoo is generally considered as one of the world’s most user-friendly business management software for the successful operation of finance, retail, and a variety of other sectors. Besides that, the